| NORSK Lithium: Future-Proofed Design |

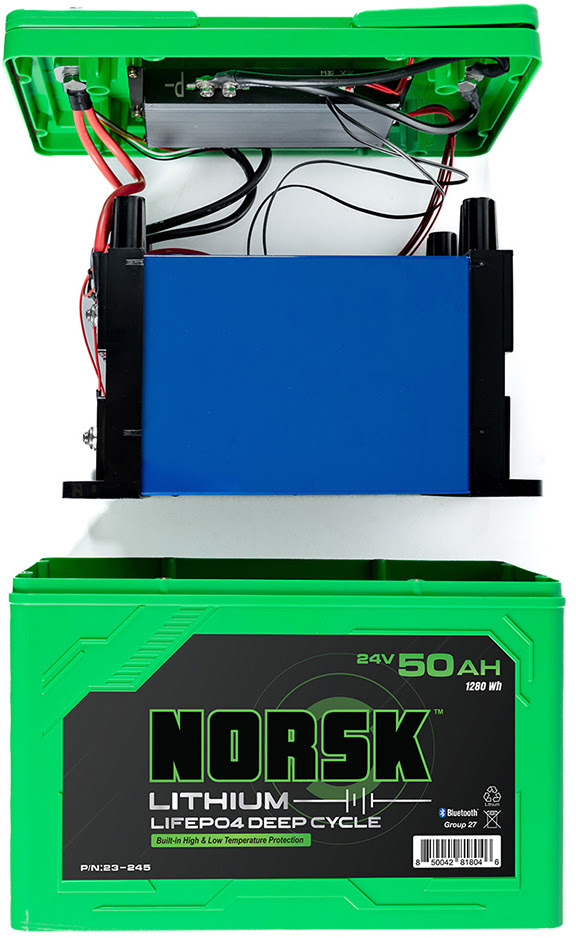

| NORSK Lithium products offer a unique case design that allows serviceability, upgradeability, improved longevity, and eco-friendly lifespan |

| New Hope, Minn. (May 31, 2023) – The marine lithium battery industry is bursting at the seams with companies putting out “me-too” batteries of marginal quality only distinguishable from each other by the color of the label stuck to the front of the case. As such, there’s no real advantage choosing one lithium marine battery over another as these companies don’t possess any engineering capabilities or commitment to producing a truly great product with original features and capabilities. They simply order what the last company ordered and change the label. “NORSK Lithium is not a follower in this ‘me-too’ marketplace,” says NORSK Lithium CMO, James Holst. “And we reinforce this claim by demonstrating a new level of commitment to innovation and problem-solving through manufacturing stand-out products that will benefit the angler or boater. For starters, our 100% serviceable proprietary lithium battery case design is truly unique in the marketplace, just one example.”One of the issues with most marine lithium batteries is they’re sealed up with no way to get to internal components. So, if a customer experiences performance issues with most lithium marine batteries, it’s game over. In fact, you’d need a saw to cut the battery apart to look inside. And then there would be no way to seal it back up and put it back into use. These batteries end up in landfills across the country. |

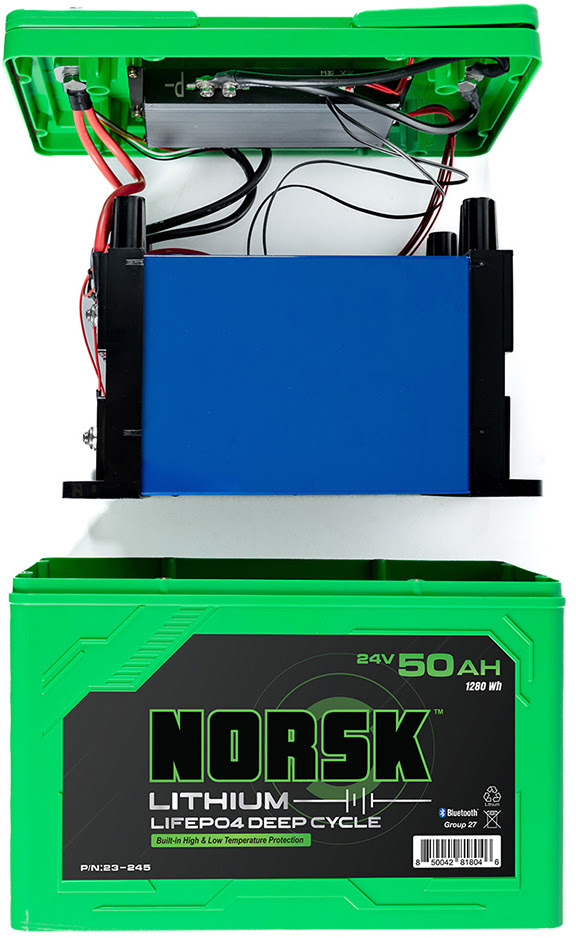

| NORSK Lithium: Easy ServiceabilityOn the contrary, NORSK Lithium’s unique lithium battery case allows a certified NORSK Lithium technician to safely open the battery and repair, replace, or upgrade any requirement, then close it back up, returning the battery to good-as-new status. First, NORSK Lithium utilizes prismatic cells, which are incredibly reliable and will last forever and a day. Inevitably, if something does fail in a NORSK battery, it’s going to be a temperature problem or BMS module, components that are nowhere near as costly as the entire battery itself. If you have a BMS module that goes bad—which is pretty rare—NORSK Lithium can replace it and make the battery as good as new. That said, the NORSK Lithium case design allows the company to double-stand behind the product and take care of customers. NORSK Lithium can repair or replace just about anything, which should bring peace-of-mind to any angler or boater who makes the investment in NORSK Lithium power solutions. NORSK Lithium founder and Engineering Director, Derek A., comments: “The biggest factor in our case design was offering serviceability, allowing technicians the ability to open the battery up and repair or replace cells or any electrical component.”“Necessity is the mother of invention,” adds Holst. “First, we utilize prismatic versus cylindrical cells which will last the full extent of our 10-year-warranty. Secondly, we are not a fly-by-night company; NORSK Lithium is going to be here for a long time. Our parent company is Sea Foam. So, we’re not one of those companies that’s going to run into the marketplace, offer a 10-year-warranty and then close up shop and disappear. We’re going to be here when your kids are shopping for boat batteries.” |

| NORSK Lithium: Future-Proof UpgradeabilityThe impetus for NORSK Lithium’s unique marine battery case design was to offer a 10-year-warranty and actually mean it. If you offer a decade warranty and BMS modules or temperature probes fail, previously the only option from other battery companies was to tell the customer to go away or send the customer a brand-new battery, disposing the problematic battery into a landfill. Those options were not acceptable to NORSK Lithium. It would be like replacing your entire truck tire because the air cap fell off. That was NORSK’s approach to the serviceable case design: Why replace the entire battery if components are serviceable?Holst remarks: “From day one, our goal has been to provide exceptional customer service and longevity and keep batteries out of landfills. NORSK Lithium prismatic cells are designed to last 4,000+ cycles, which, in real-world terms, is a battery that will last as long as the boat you put it in. This is why it’s so important to us to be able to put the cells in a case that actually allows us to service the product for our customers.”Right now, LiFePO4 is the best lithium battery chemistry available, absolutely no doubt about it, but NORSK Lithium is privy to more advanced designs and chemistries coming down the pipeline. The idea that lithium marine batteries will be using the same LiFePO4 chemistry in 3 – 5 years that we’re using today, given the pace of current research and development into lithium battery cells, would have to be seen as incredibly naive to anyone paying attention. Eventually, an angler might be able to, for example, get double the runtime of what NORSK is currently offering in the same size cell. As such—with its case and modular cell design—NORSK Lithium anticipates being able to offer a cost-effective upgrade option to customers when these new chemistries emerge. “Every time an angler or boater purchases a NORSK Lithium product we’re entering into a long-term partnership. Lithium cell technology is advancing very fast and we want to offer our customers the option to upgrade as these new chemistries emerge,” notes Holst. “Now, if you’re a company not willing to invest in a serviceable case design, when cell improvements do become available, the alternative is to look a customer in the eye and tell them that the lithium battery they purchased a few years back is now out-dated and to have access to the new technology they need to discard their current batteries and buy a completely new set of batteries. As my grandfather used to say, that dog don’t hunt.” |

| Improved LongevityNORSK Lithium also considered battery longevity when designing their unique battery case. First, the internal case design allows appropriate air flow between the cells, important because you don’t want cells overheating. Most lithium battery companies pack cells internally in a bundle and wrap them in tape and foam which doesn’t allow for much heat dissipation and cooling. Likewise, the spacing between prismatic cells in NORSK Lithium’s heated batteries allows heat to actually get to all the battery cells—not just the outside cells close to a temperature probe. NORSK Lithium founder and Engineering Director, Derek A., offers: “Our internal rack design holds our prismatic cells in place in a way that spaces them a little bit, which is unique compared to other lithium battery designs where cells are sandwiched and taped together. By having the space we’ve allowed, we provide the room needed to adequately heat and cool the cells.”NORSK Lithium’s internal plastic rack design also greatly reduces vibration; nothing bounces inside a NORSK Lithium battery. If you pick up a NORSK Lithium battery and shake it, nothing moves, unlike competitive products. Over time, when you’re out on-the-water in big waves, the cells in other lithium batteries shift and spot welds and other connections are stressed. This invariably leads to performance issues. |

| Eco-Friendly DesignNORSK Lithium also approached their marine lithium battery design with a level of environmental consciousness. “Given our serviceable case design, we’re not throwing thousand dollar batteries into the landfill because of an issue with something small and serviceable like a BMS module or temperature probe. NORSK Lithium is committed to making sure that the lithium customer gets their full life-cycle out of the battery. If something does go wrong with the battery, we can fix it and get it back into service—it’s not just thrown into a landfill.”Additional Case FeaturesNORSK Lithium also departed from the typical cylindrical terminal post design found on most marine batteries.Derek A. comments: “The terminals on the cover have a square base so you cannot over-torque them. Standard lithium battery terminal design is a cylindrical post where it connects to the plastic which can be easily over-torqued and lead to cracked plastic.”“We also increased the strength of the handles, a known weak point in many marine lithium battery designs.” |